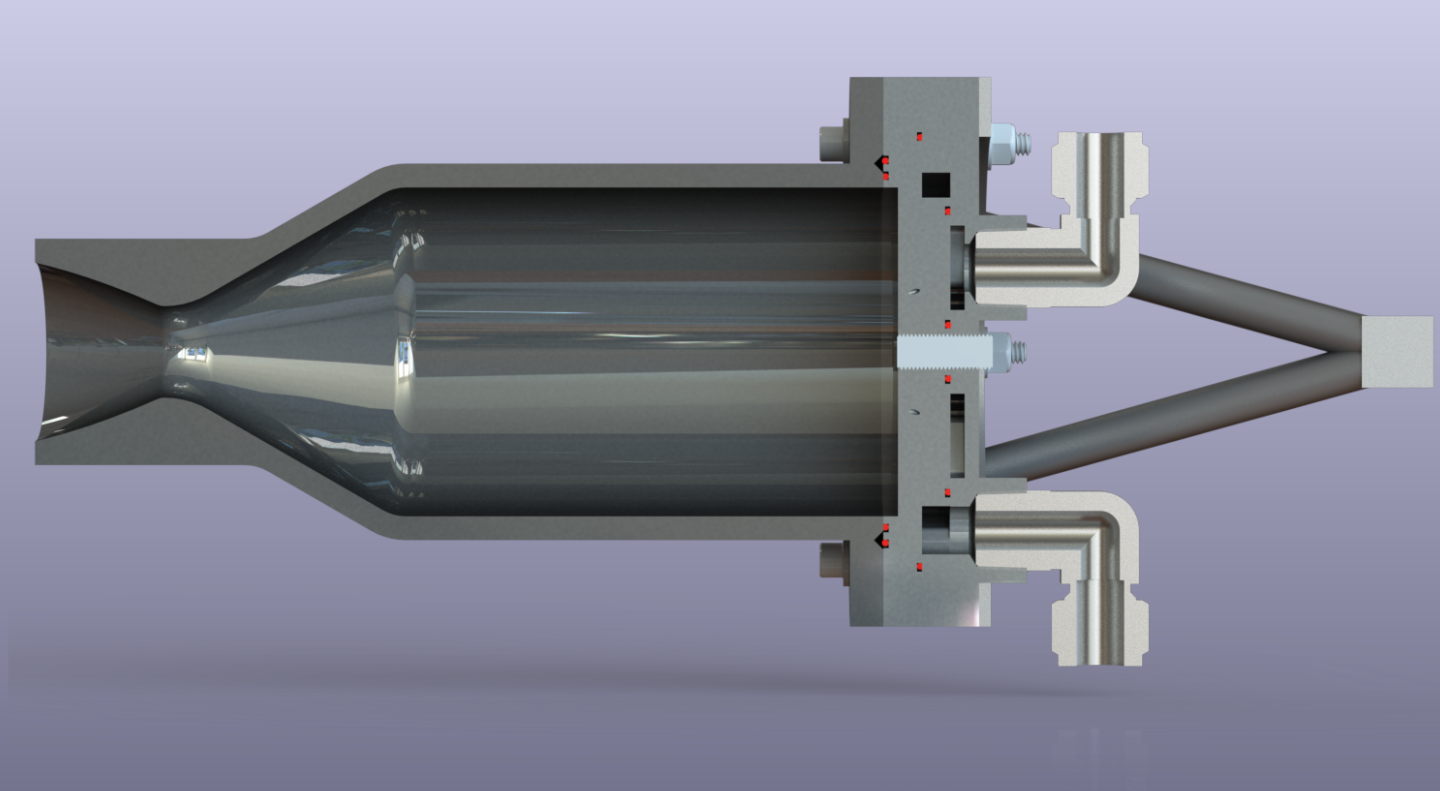

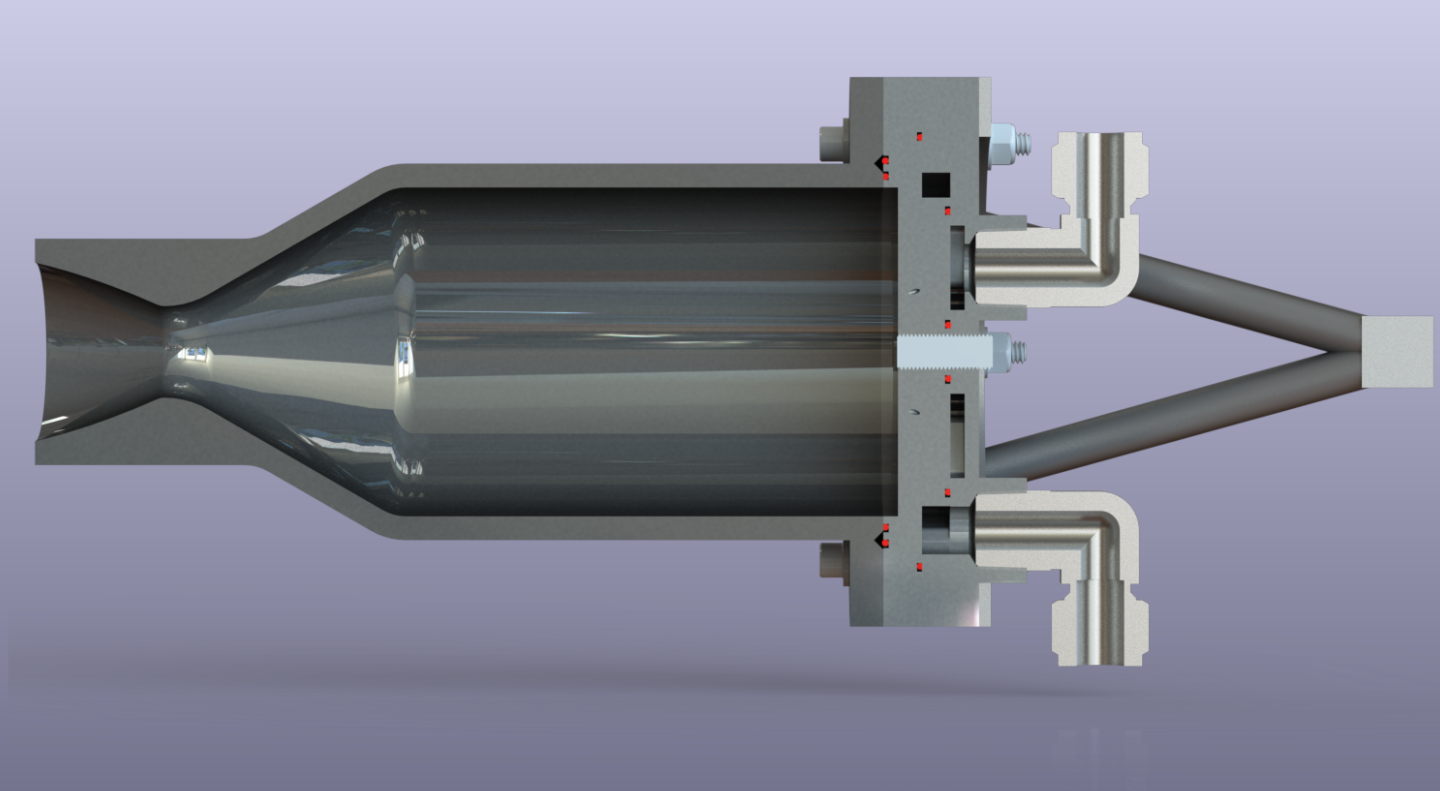

Liquid Rocket Engine

Pressure-fed, liquid bi-propellant rocket engine with liquid oxygen and kerosene propellants.

Sun Devil Rocketry, Arizona State University's oldest rocketry student organization, helps prepare students to become leaders in aerospace and engineering through meaningful projects, interactions, and experiences. The organization is funded by ASU, and provides members the opportunity to explore and make hands-on contributions to propulsion and high-powered rocketry collaborative engineering projects. Members design, manufacture, and launch high-power rockets for competitive and experimental purposes. Additionally, SDR's award-winning outreach program exposes hundreds of K-12 students to rocketry each year.

I have been involved with Sun Devil Rocketry since my first semester freshman year. I joined the introductory challenge team and worked with a team of 12 students over the course of the school year to design and launch a high-powered model rocket to reach an altitude of one mile. I then joined the liquid propulsion team, and began working on architecting an avionics system for a liquid rocket engine, which I am still working on today. Since then, I have held multiple leadership roles within the organization. I was president and liquids team lead during the 2021-2022 school year, during which I effectively restored the organization to its pre-COVID state after more than a year of virtual work and activities. Additionally, I founded a new avionics team both to support active projects within the organization and to apply my interests in electrical engineering and software to rocketry.

Sun Devil Rocketry participates in multiple Tripoli high-power rocketry launches each year. In order to recruit less experienced students into the organization, SDR hosts an introductory challenge in which two teams compete to design a rocket to meet a specified design criterion. Past challenges have included target apogee altitudes, racing, carrying an important payload, and the classic egg-drop challenge. More experienced members design their own rockets using SDR resources and get amateur rocketry certifications. Often, SDR members will collaborate with their personal rockets to build more powerful rockets with complicated subsystems.

In order to give back to the community and promote STEM education Sun Devil Rocketry participates in a number of outreach events throughout the school year. The most popular of these are our "classroom takeovers", in which we visit an elementary school classroom to teach students about the science and engineering behind rocketry and space. After a lecture/QandA session, we build small Estes model rockets with the kids and launch them on the school's recess field. The event is a lot of fun for everyone, and an extremely rewarding experience.

The liquid propulsion research team is Sun Devil Rocketry's largest project team, and aims to teach members about liquid propulsion systems through a hands-on project. The team has been working for three years to develop a liquid rocket engine, having started from scratch in the fall of 2019. Work on the liquids project involves the design and simulation of complex fluid systems, testing of individual engine components, component manufacturing, control system design and sensor interfacing, design reviews, and lots of documentation. You can learn more about the project here or on the Sun Devil Rocketry website.

The solid propulsion research team conducts research on the performance of solid rocket propellants and builds testing infrastructure and custom solid motors. Sun Devil Rocketry has access to its own mixing lab shown in the image to the right, which it uses to mix its own propellants. Propellant characterization is achieved through the use of an in-house manufactured acoustic strand burner, which times the propellant's burn rate and measures chamber pressure. The team is also building a static thrust stand to use in hotfire tests and to experimentally measure the thrust curve of custom solid motors.

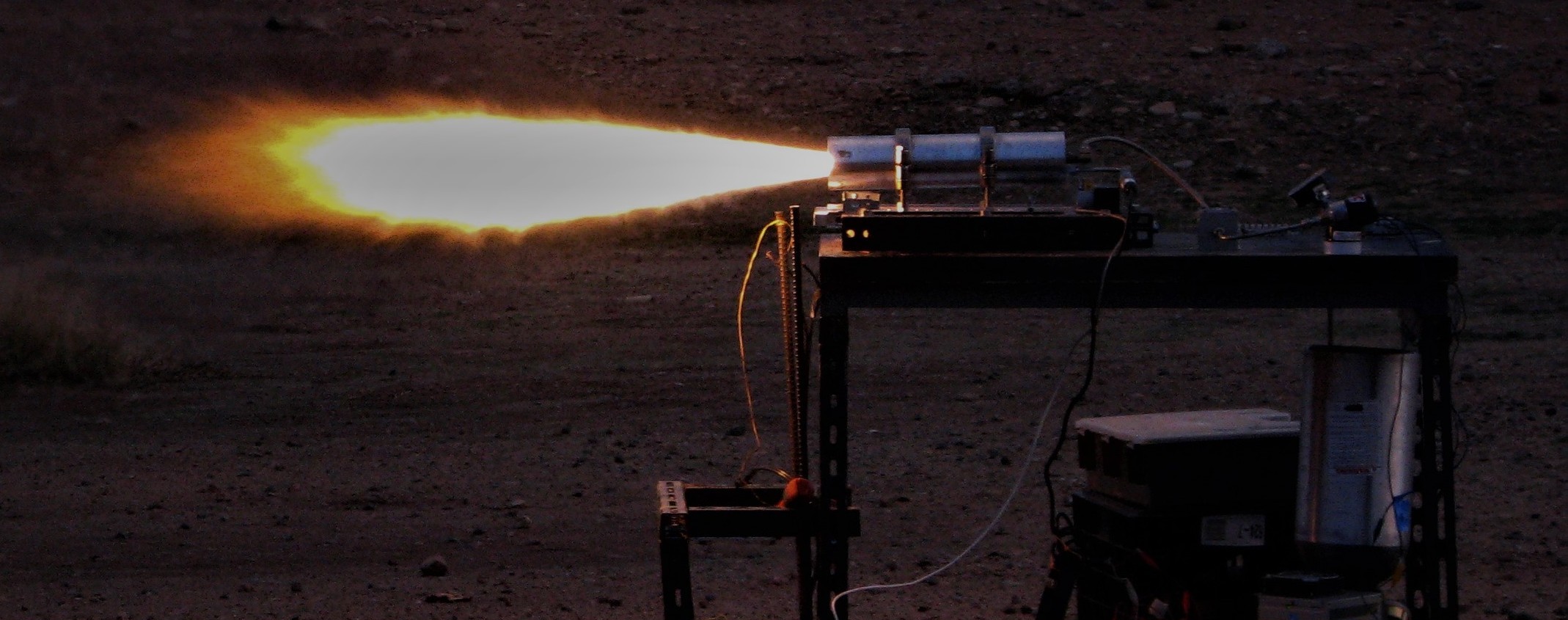

The hybrid propulsion research team conducts research on the performance of hybrid propulsion systems which make use of both liquid and solid propellants. The team has conducted several hotfire tests in the past, and is currently working on an in-house designed and manufactured vortex-swirl injection hybrid rocket engine. The team works with both liquid and solid rocket propellants, and therefore often collaborates with both the liquid and solid propulsion teams. The current project has been in development for a little under two years, and has also been used as part of ASU's FURI research program.

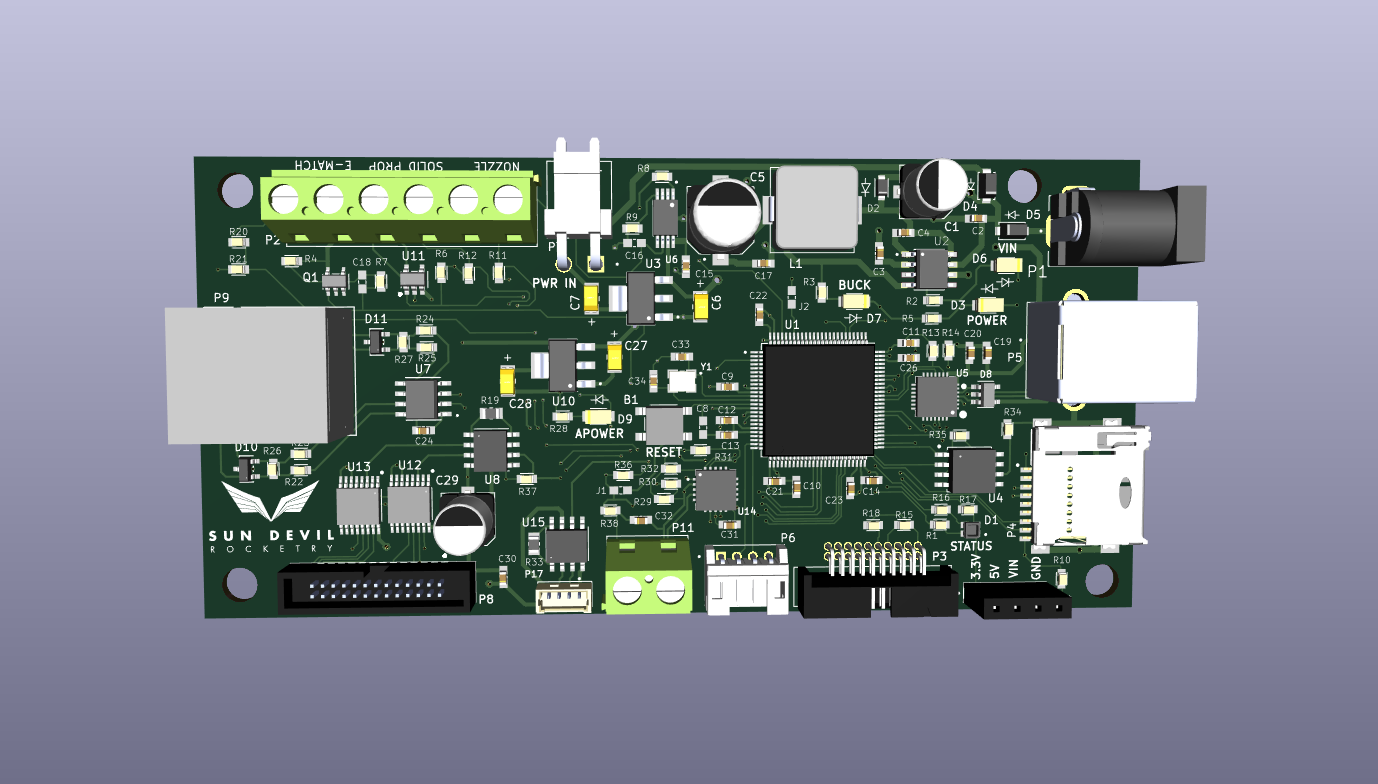

The avionics team is the newest of Sun Devil Rocketry's project teams, which I founded during the spring 2021 semester in response to a renewed interest in more complicated high-power rocketry projects, and a common need amongst the propulsion teams for electrical and software engineering skill sets. As the primary team project, the team aims to develop SDR's first custom flight computer, a goal which has been discussed for years but had never amounted to much due to a lack of technical knowledge. The team is also responsible for all of the club's propulsion avionics. Since the avionics needs of all the propulsion projects are very similar, this model has accelerated the technical development of the propulsion projects by facilitating collaboration between propulsion teams and allowing them to focus on engineering problems within their area of expertise.

Pressure-fed, liquid bi-propellant rocket engine with liquid oxygen and kerosene propellants.

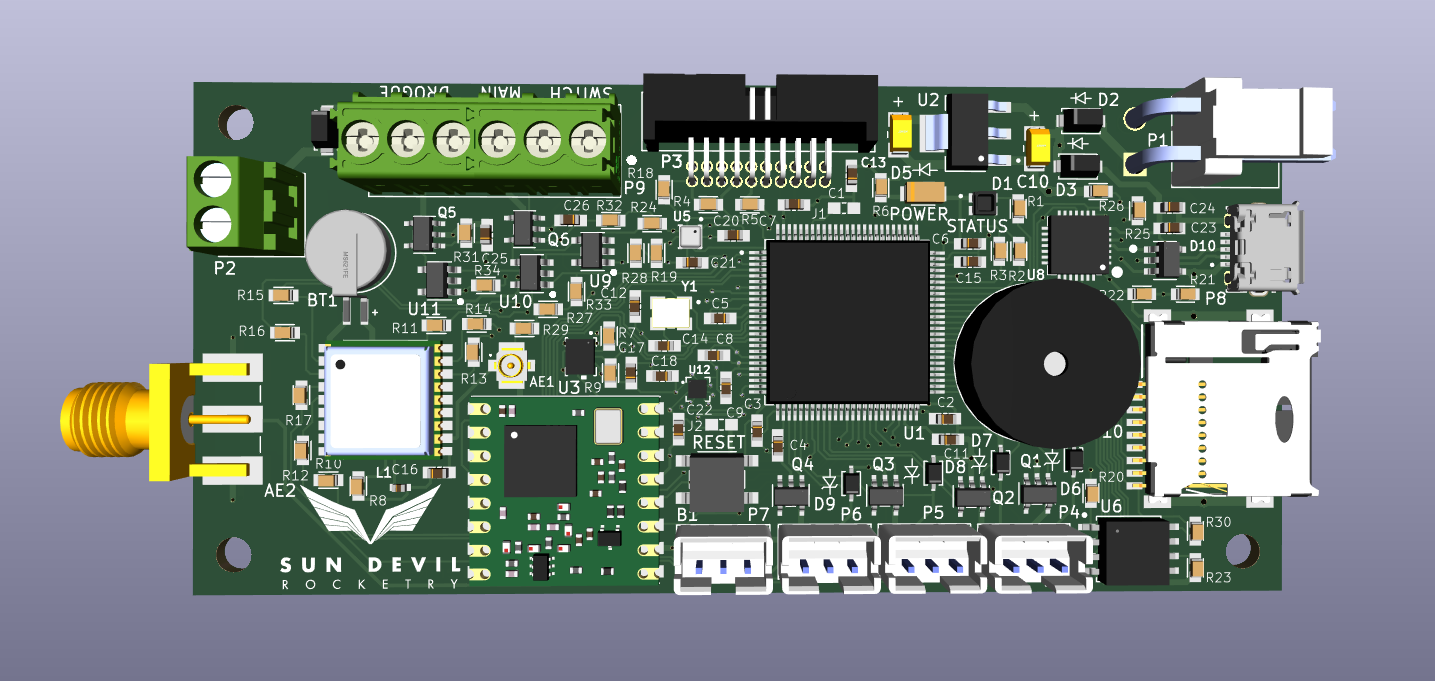

Embedded processor for the liquid engine. Implements remote propellant feed sequencing, ignition, data logging, and analog sensor interfacing

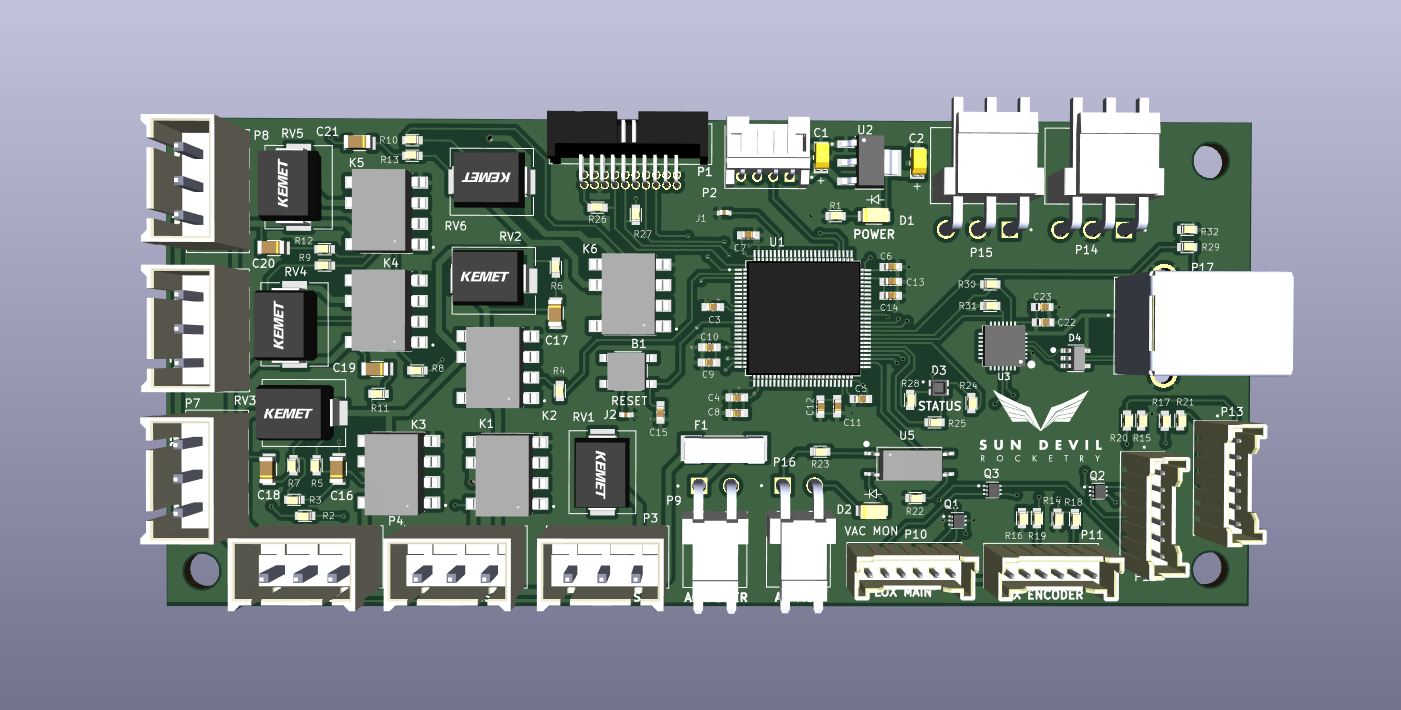

Input/Output processor implementing simple valve actuation commands for AC powered solenoids and stepper motors with feedback sensors

Prototyping platform for flight control projects with embedded IMU, GPS, telemetry, and data logging peripherals.

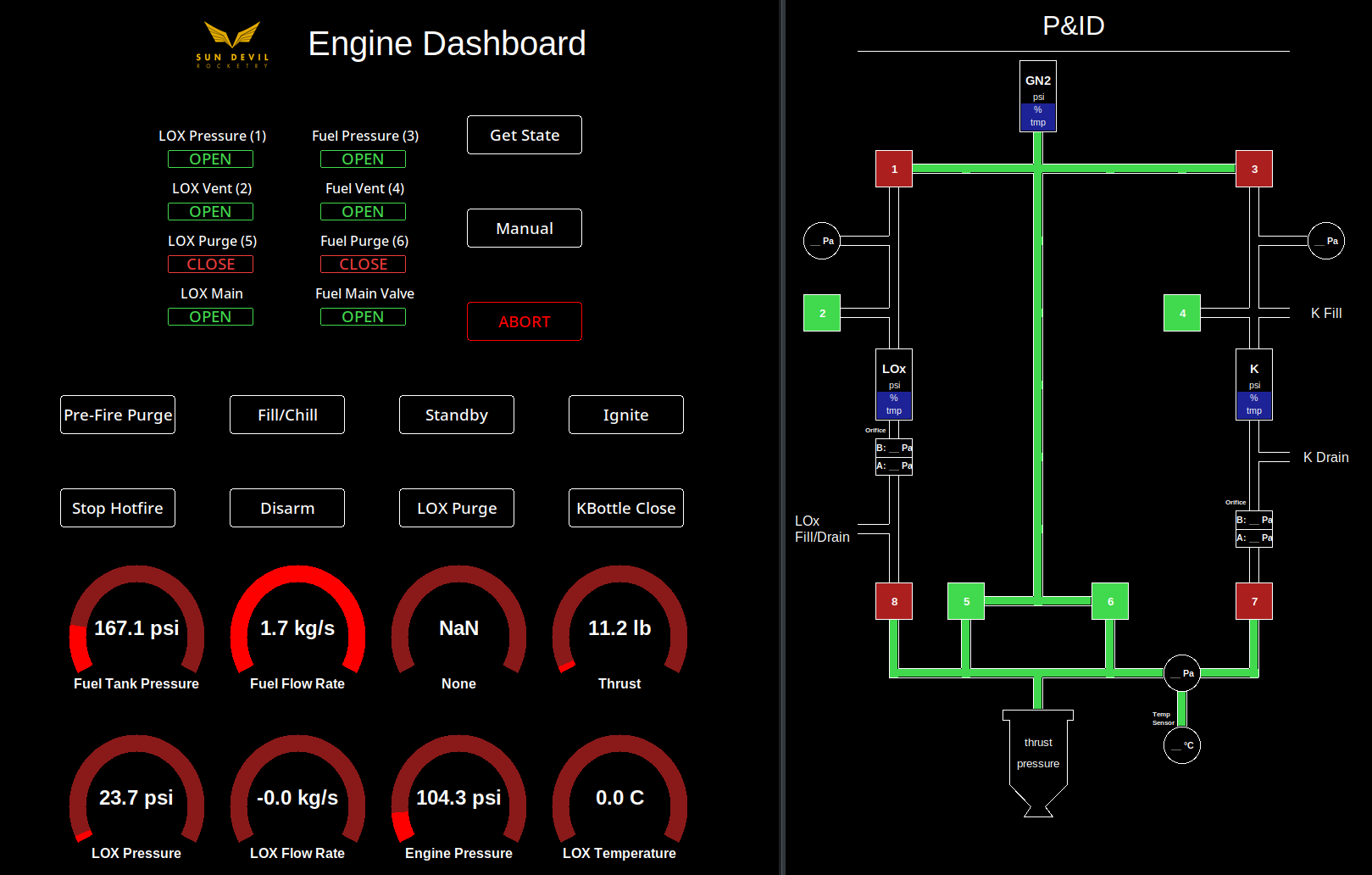

GUI for controlling SDR's liquid rocket engine during hotfire tests

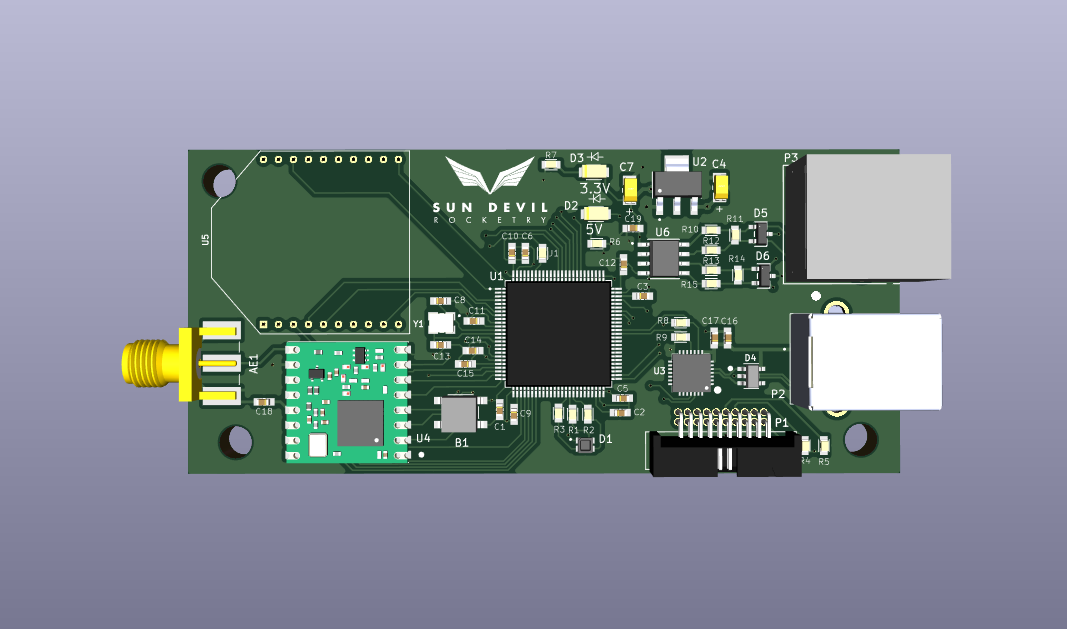

Serial interface providing ethernet, Xbee, and LoRa interfaces to PC over USB

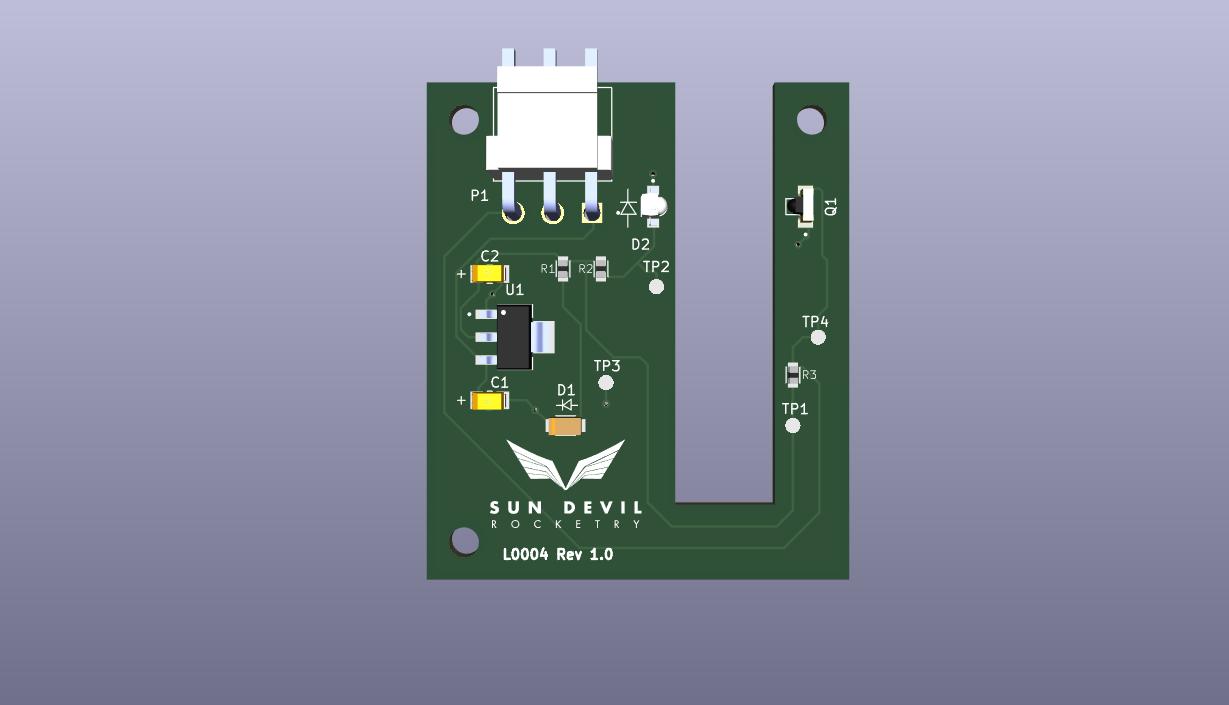

Optoelectronic sensor for calibrating motor absolute position upon system startup by detecting obstructions to the sensor optical path

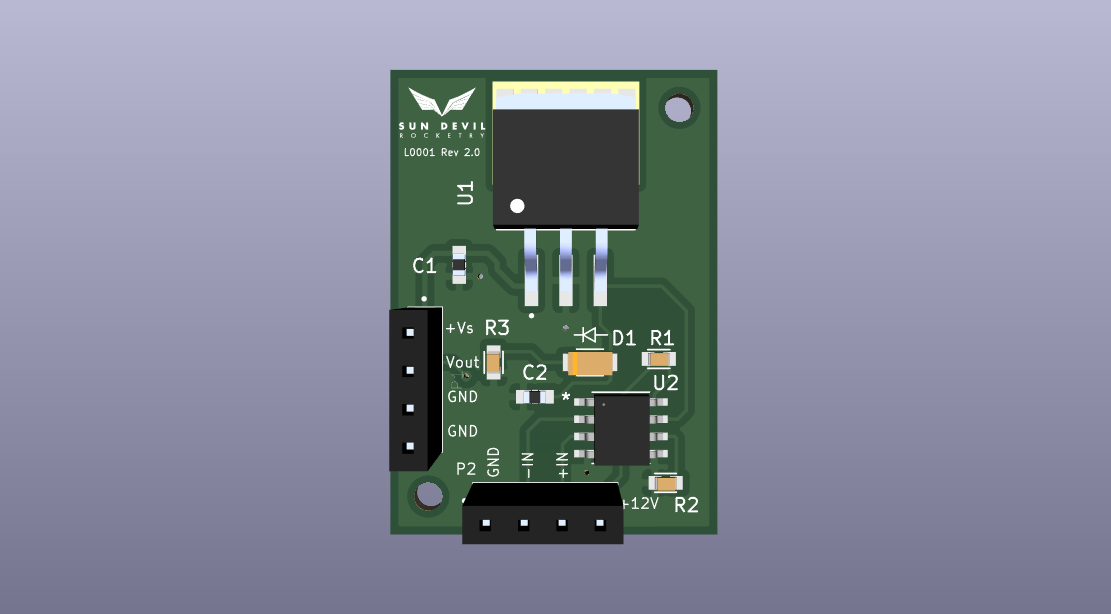

Prototyping amplifier board for differential pressure transducer and load cell outputs with an instrumentation amplifier IC

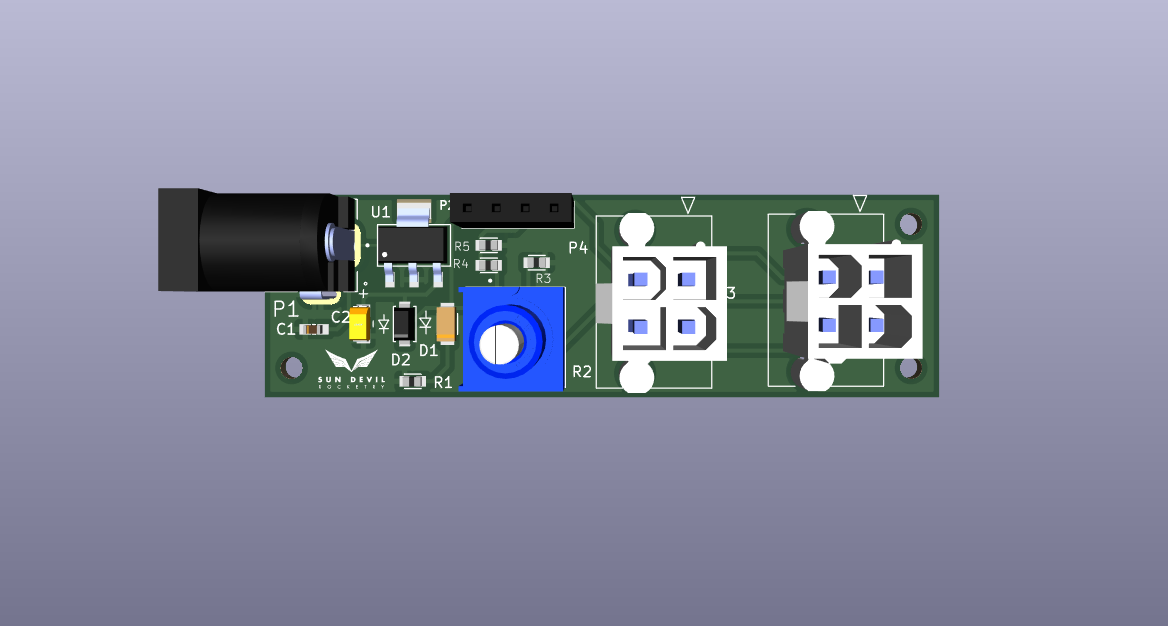

Electronics testing board, generates an adjustable differential output to emulate pressure transducer output